What is laminated glass ?

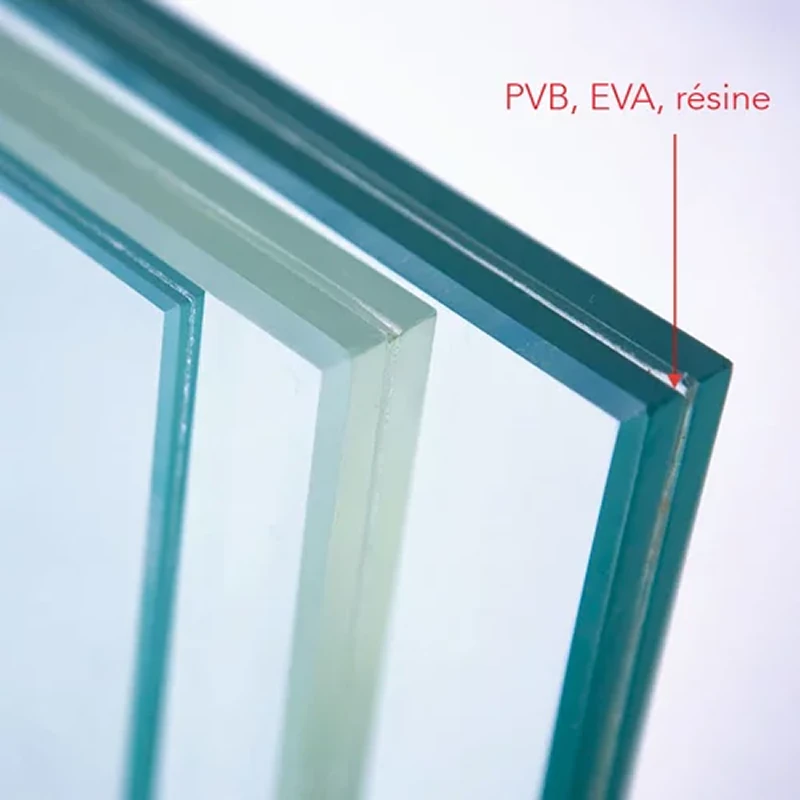

VIT STOP CHOC custom-made laminated glass consists of layers of glass and PVB or Evasafe films, forming a solid, impact-resistant unit that remains in place even after breakage. This product is particularly suitable for applications requiring enhanced safety, especially in high-risk areas.

The advantages of custom laminated glass

Technical characteristics of custom laminated glass

Definition of laminated glass compositions

Classification of laminated glass

This classification is expressed according to:

• 1 for a drop height of 1200 mm

• 2 for 450 mm

• 3 for 190 mm

1200 mm and has withstood level 1 stress.

The EN 356 standard defines the ability of glazing to withstand projectiles.

|

Base composition in annealed glass according to NF EN 572-2 Reference: NF EN ISO 12543-2 (nominal thickness in mm) |

33.2 | 44.2 | 55.2 | 66.2 |

| 6.8 | 8.8 | 10.8 | 12.8 | |

| Maximum surface in square meters (m²) Glass considered as guardrails without prior testing (according to DTU 39) |

0.50 | 2.00 | 4.50 | 6.00 |

– Minimum rebate depth (pf) = 15 mm;

– The profiles forming the rebate must meet the requirements of paragraph 8.3 of NF DTU 39 P1-1 :

The profiles forming the rebate must have sufficient rigidity, ensuring a deformation less than or equal to 1/300 of their length under 800 Pa, applied on the infill element;

– For glazed walls, the top rail, when located within the protection height, must be validated under an M50/900J impact test, in accordance with P 08-302.

Shop windows and facades : Provides security against break-ins while allowing maximum visibility.

Precaution when installing insulated glass balustrades.

| Impact-side glazing | Opposite-side glazing | ||||||

|---|---|---|---|---|---|---|---|

| Annealed | Heat-strengthened | Tempered HST 1C1 | Tempered HST 1C3, 1C2 | Tempered HST NPD | Laminated PVB 1B1 or Other 1B1 and P1A | Other laminated | |

| Annealed | NO | NO | YESa) b) | NO | NO | YES | NO |

| Heat-strengthened | NO | NO | YESa) b) | NO | NO | YES | NO |

| Tempered 1C1 | YESa) b) c) | YESa) b) c) | YESa) d) e) | YESa) d) e) | YESa) b) c) | YES | YESa) b) |

| Tempered 1C3, 1C2 or NPD | NO | NO | YESa) b) | NO | NO | YES | NO |

| Laminated PVB 1B1 or Other 1B1 and P1A | YESc) | YESc) | YESe) | YESe) | YESc) | YES | YES |

| Other laminated | NO | NO | YESa) b) | NO | NO | YES | NO |

a) With residual protection according to NF P 01-012:1988.

b) Justification of non-breakage of the 1C1 component.

c) Justification of non-breakage of the opposite-side glazing.

d) Justification of non-breakage of either component.

e) Justification of non-breakage of the opposite component if it is thicker than 10 mm.

Applications

Partition

Discover

Windows

& doors

Showcase and

glass roof

Veranda

DiscoverCustom laminated glass :

the ideal solution for your projects

FAQ – Everything you need to know about custom laminated glass

What is STOP CHOC laminated glass ?

plastic film, designed to offer increased safety in the event of glass breakage. It keeps fragments in place and protects against the risk of injury or break-ins.